Renowned Standing

Due to skills we hold, both large and small roll-out firms want to benefit from our knowledge and expertise.

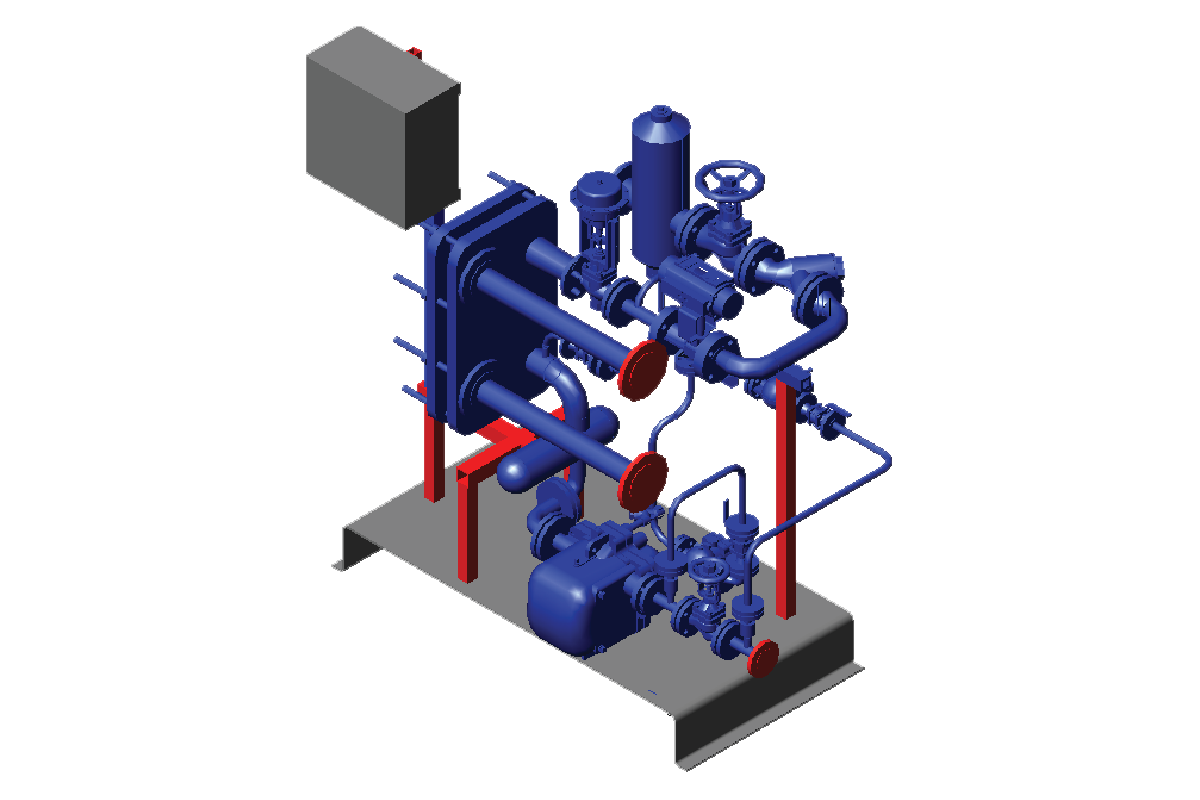

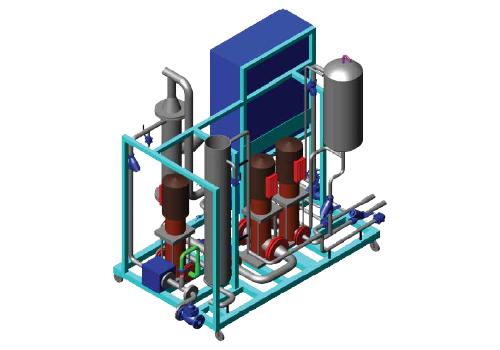

Process Flow Diagrams (PFDs) that simplify complex systems and improve project efficiency.

At Gsource, we take pride in delivering detailed and user-friendly Process Flow Diagrams (PFDs) that provide a comprehensive view of industrial process equipment and their relationships. Our diagrams involve critical elements such as pipe sizes, flow directions, intersection designs & equipment identification, ensuring clarity in every aspect of your project. Committed to meeting international standards, our PFDs also consider all regulatory and safety requirements.

They are also important tools for visualizing complex process systems, highlighting the interconnections and sizing of various components. These diagrams allow you to grasp the entire workflow, facilitating effective communication, collaboration & optimization within your projects. Whether you're working on wastewater treatment facilities or drainage utilities, Gsource is your trusted partner for creating accurate and effective Process Flow Diagrams that drive your projects forward. Let us help you bring your process designs to life!

Process Flow Diagrams (PFD) can become a difficult task at times and also require detailed and expert advice. Outsourcing these services can benefit you in certain ways

Here, at Gsource, we have skilled professionals and experts who provide our clients with precise and accurate designs, diagrams & others for PFD. We have advanced tools for diagrams and other purposes to get you apt results that also comply with codes and regulations.

Designs for flight operations, maintenance processes & safety protocols.

Optimized flow for logistics, route management & efficiency in transit systems.

Diagrams for automation processes, control systems & integration workflows.

Layouts for manufacturing processes, assembly lines & quality control.

Flows for production cycles, supply chain management & product distribution.

Detailed representations of operational workflows, maintenance procedures & safety measures.

Integrated process flows for production efficiency, quality assurance & resource management.

Due to skills we hold, both large and small roll-out firms want to benefit from our knowledge and expertise.

We use high-tech solutions to understand design and construction requirements for Process Flow Diagram Services.

We have an R&D team that can handle vast data collection, which can feel like a task for other companies.

Timely actions and efficient outputs minimize delays, maximize productivity & ensure prompt PFD services for our clients.

The data used by us for creating topographic maps, volume calculation & distance measurements provides results to the point.

The experience that our team holds is what sets us apart. With training programs, our team of 300 members can deliver top-tier results laid over a 30,000-square-foot Class A Office space.

We are active members of national and international surveying, architectural, engineering & geospatial organizations.

As a service provider, we’ve supported and served companies across the US. Our dedication produces excellent quality that propels industry success.

Our PFD services package includes the creation of clear & comprehensive process flow diagrams, detailing equipment, process flow & operational parameters.

Yes, we provide PFD services for both small and large-scale industrial projects, ensuring that your process flow diagrams are precise & suitable for your project size.

To start a PFD project, schedule a consultation with us to discuss your process needs & we’ll create a detailed plan & timeline for your diagrams.

Yes, we can revise and update existing PFDs to reflect changes in your processes, ensuring that your diagrams remain accurate & up-to-date.

The main difference between a process flow diagram (PFD) and a piping and instrumentation diagram (P&ID) is the level of detail and the information they include. Both PFDs and P&IDs are important tools for engineers to understand and design industrial processes. However, the differences between them can vary between plants, and most plants have established standards for creating and modifying these documents.

(Enter captcha image text in box)

At Gsource Technologies, we’re ready to help! Tell us what you need, and we’ll connect you with the right experts.